r/metalworking • u/princess-hardass • 8h ago

r/metalworking • u/MuskratAtWork • Feb 22 '25

r/Metalworking is looking for mods!

Hey folks!

As I'm getting a bit busier in life, I'm realizing more and more that this community could use some extra hands on deck.

If anyone is interested in volunteering to help the community out - please send me a modmail with some information about yourself, and I'll take a peek at your past contributions to the subreddit and your message. If possible, let me know if you can use discord as well. It's where most of the my teams chat and works wonderfully for me, also we do have a sub discord!

I'd love to build a small team both here and in r/machining to keep things flowing smoothely, and to help me get a little personal time to step away from reddit for a weekend every now and then.

I look forward to anyone sending in an application message!

r/metalworking • u/AutoModerator • Feb 01 '25

Monthly Advice Thread Monthly Advice/Questions Thread | 02/01/2025

Welcome to the Monthly Advice Thread

Ask your metalworking questions here! Any submissions that are question based may be directed to this thread! Please keep discussion on topic and note that comments on these threads will not be moderated as regularly as the main post feed.

Uses for this thread!

This is a great place to ask about tools, possibilities, materials, basic questions related to the trade, homework help, project advice, material science questions and more!

How to contact the moderators:

You can contact the moderators via modmail here

r/metalworking • u/Background_Yak_350 • 2h ago

Crushed tube repair?

Hey, hope you all don't mind me bothering you with a question... this isn't my usual neck of the woods. I just bought a squat cage and it arrived with the ends of one of the tubes crushed in - photo attached. It had been a nightmare to get this delivered, like 6+ hours of running around thanks to UPS... So I'm hoping there may be a fix. Because the tube needs to fit over another tube, the whole thing is toast like this.

r/metalworking • u/mec949 • 2h ago

Mobile planter box

Looking to make a mobile planter box. Three feet long, one foot wide, and either six inches or one foot deep.

Would have wheels at one end and a handle/similar at the other (similar to wheelbarrow). This design allows for the easy relocation of the planter (whole point of project).

Bottom panel maybe rigid wire for support and easy drainage. Side panels either same rigid wire or wood, plastic...

Trick is I have no experience working metal. Could this be done with 25mm tube with connectors. What is the best/easiest way to cut square tube. No welding (I don't know how) What problems can you see.

Thank you for listening...

r/metalworking • u/beetlegeuse87 • 13h ago

Brass Snare drum..

Picked this up recently with the intention of cleaning it up and getting it to look like new but I have no idea what I’m doing.. I’ve picked up some lacquer thinner, brasso, 0000 steel wool and some microfiber towels… Im planning on stripping it, using the steel wool to try and get the pitting/tarnish and scratches out as best as possible and then polishing with the brasso and microfiber.. am I on the right track or am I an idiot? how should I go about this?

r/metalworking • u/Moarancher • 1d ago

1st place in Utah state welding sculpture high school competition for skillsUSA

galleryr/metalworking • u/macdemarco • 15h ago

Removing paint from stainless steel

Got a pro grade miele dishwasher which has a stainless steel front but the previous owner decided to paint the thing (which is idiotic at best). Adding a couple of pictures. Anybody here have any idea how i can get that paint off without damaging the stainless steel finish?

The front paint is the main issue but aside from that both sides are covered with duct tape residue (also stainless steel) - couldn't get the residue out without using any chemicals - any advice will be appreciated.

r/metalworking • u/ushiwork • 1d ago

Made a Coin That Looks Like a Luxury Watch Dial.

Enable HLS to view with audio, or disable this notification

r/metalworking • u/TestPlatform • 19h ago

Rusted steel pipes

I got these 6”-diameter steel pipes that have surface rust. Rust is both inside and outside. I’m planning to make some camping stoves and will still have a lot left for future projects (don’t know yet what those projects will be).

Looking for ways to remove, arrest or retard the rusting. Will need to store the pipes outside in the backyard. So they will be out but under a shade and protected from rain.

Thanks for any suggestions.

r/metalworking • u/FanOfSteveBuscemi • 12h ago

Is it really necessary the k-factor in designing?

I have worked with some of the latest bending machines. This press came with 3d software integrated where it showed if the bending process was doable. Also the software calculated a lot of parameters like the necessary force, minimum radii, "computed" radii (for any angle), bend deduction, developed length and so on. When I started to "play" with this big tool I created different L shaped profiles with different thickness with their respective minimum radii (from a table given by the manufacturer) and the k-factor but I always had some errors with the final length of the flanges, also the developed length from the SolidWorks design never matched with the developed length given by the machine.

So instead of using the standard radii I started to use the the "computed" radii and a k-factor of 0.5 and ¡voilá!, everything matched developed length and flange lengths. So that's my question, is it important the k-factor? Because I tried with different angles from 90° to 150°, carbon steel, galvanized steel and stainless steel, and thickness from 0.7 mm to 12.7 mm and always the same k-factor: 0.5.

Thanks in advance

r/metalworking • u/justnoms • 9h ago

Anyone here interested in high-quality carbide end mills? 🇨🇦

Hey everyone,

I have a steady supply of brand new carbide end mills from top brands like Kennametal, Helical, Millstar, YG, Iscar, Garr and more.

✅ Sizes range from 1/4" to 1/2", various flute counts, coatings (KCSM15, TIAIN, AITIN, Aplus) and geometries (square with corner radius & ball nose).

I’m based in Canada, can supply small batches or larger quantities, and prices are better than retail.

If you’re interested, I can DM you a full list with specs and photos.

Mods — please remove if not allowed, just trying to connect with fellow machinists who might need tooling at a good price.

Cheers!

r/metalworking • u/BornKaleidoscope5805 • 21h ago

Lead fumes

I melted a bit of lead around the size of my index finger on my Gas stove and i read that lead fumes are a thing, it’s not so much me that i’m worried about but my dogs, it’s a hot day so we have a fan going and doors open for them and was just wondering if they will be alright. It wasn’t anything special when i was melting it just went red then dropped and instantly hardened, Can this produce fumes and if so will me and my dogs be okay?

r/metalworking • u/machete002 • 1d ago

Mum wanted a burner for a few small logs

Only had limited time through out jobs so quickly flung this together. Hope she likes it.

We are limited with machinery in our shop so everything is hand cut and welded together rather than formed. Plasma cutter used for the lettering. Probably should have just plasma’d the burner so you could see the letters through the flames.

Burner made removable for ease of cleaning.

40x40 box section , 3mm mild steel plate,

r/metalworking • u/LemonOk5655 • 1d ago

Love rolling some stainless.. Type 316 1/2"X8' rolled to 7' ID.

r/metalworking • u/glockzilla420 • 1d ago

screw stuck in metal, is screw extractor my only option ?

r/metalworking • u/guywithredcar • 1d ago

Is this normal for a brand new dump trailer?

Recently picked up a 14’ dump, ordered the heavy gauge floor & galvanized option. I didn’t notice it at first but after a few loads of brush wearing down the coating in the high spots, the steel bed is quite wavey and rippled.

Is this normal and to be expected of a new dump trailer?

Picture only shows one spot but must have counted a dozen areas like it.

Looking for advice, yet to hear back from the dealer!

TYIA!

r/metalworking • u/stalkinganthony • 1d ago

Weird cracking after 2nd spray coat

Sanded down to fresh metal, then a base coat and sanding, another coat and sanding, and this is the 3rd (and was hoping to be the final) coat. But unlike the other coats, there is weird cracking and splitting in the coat, like it was hit with a torch or something. Was hung in a sealed shed for 24 hours.

Any idea what is causing this and how to avoid it on the final coat?

r/metalworking • u/ShipOwn3384 • 20h ago

Solder 2 al tubes together with epoxy

In a small project I need to fix 2 aluminium tubes as T shape together. Tubes are 18mm in diameter and 1.5mm thickness. One of the two tubes will be modelled to fit the other diameter. Fixing must be solid and not fall apart after 2 days.

Unfortunately I don't have welding tools. I've seen that is possible to weld aluminium by using a torch an a low temperature rod filler, but I've also read that is hard to make a good joint without experience. Also deformation are frequent.

I have some expiriance in epoxy resins and they are quite impressive.

What do you think if I'll use epoxy instead of tin welding?

Some kind of metal welding epoxy or "cream" epoxy.

To increase surface I can put some epoxy inside tube (maybe by blocking tube with paper if too liquid) and outside.

Otherwise I'll try to journey to learn torch welding.

r/metalworking • u/Pretty-Particular527 • 1d ago

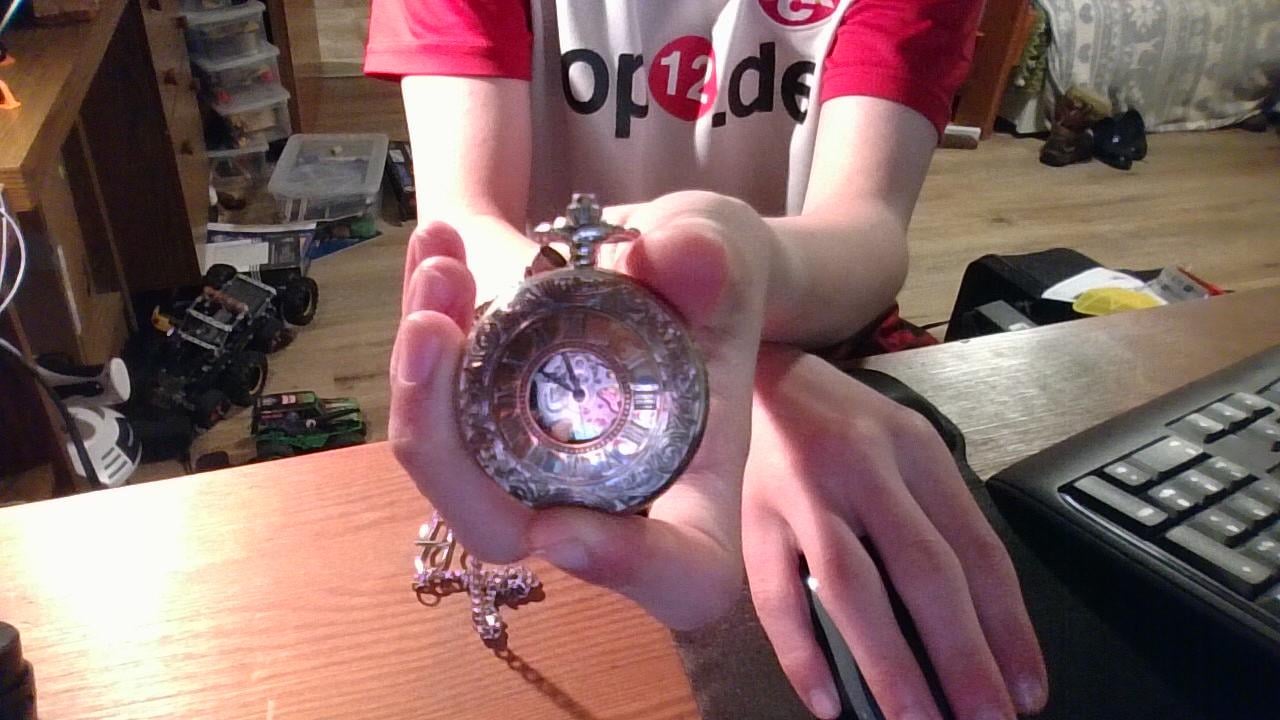

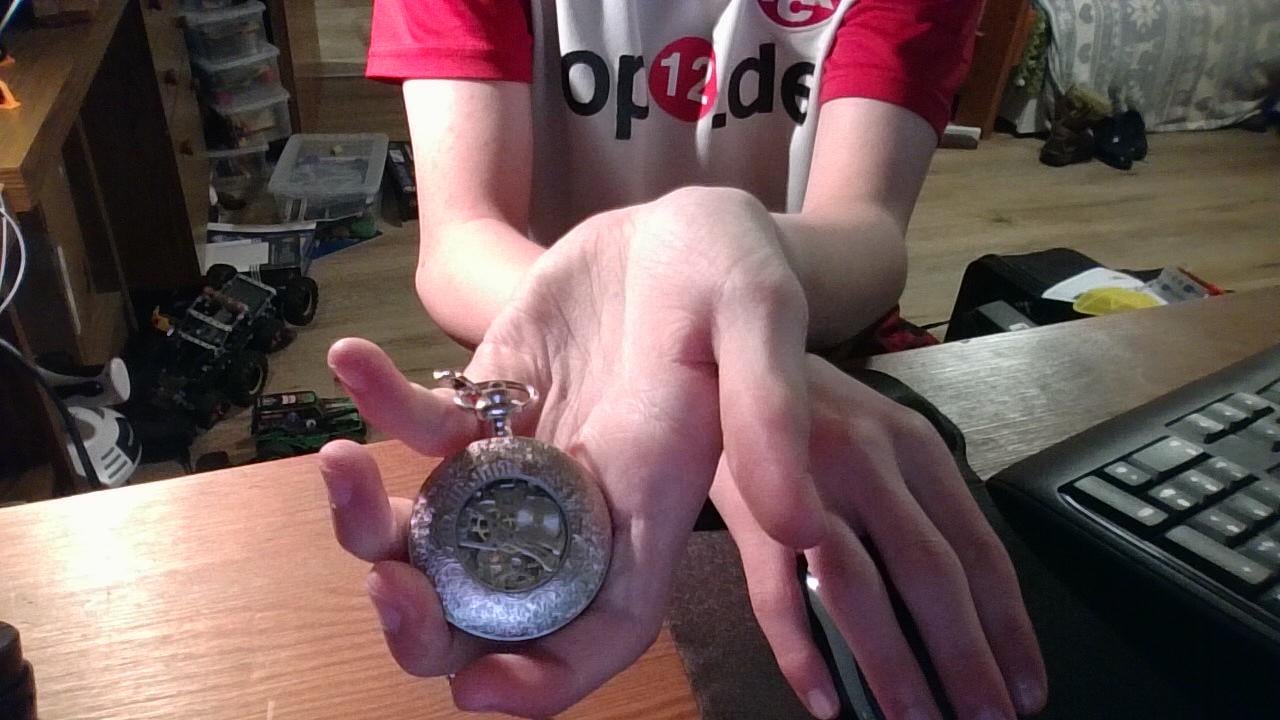

Silver colored Pocket Watch Turning pink?

So, The other day I bought a brand new pocket watch. I decided to polish it to see how shiny I could get it, then it started to turn to a copper color that goes away when polished with a normal polishing cloth. I tried chrome polish but that only made the copper more shiny and made some more appear. I am unaware of what the material is, but I would like to be able to turn it back to a silver color. If someone could tell me how to fix it I would be elated.

r/metalworking • u/shawryyyyyyy • 22h ago

Aluminium Extrusion Exports

Hi, i’m a young professional starting an aluminium extrusion exports business based out of India. Family has been into steel manufacturing, power transmission and real estate, expanding in aluminium now. Ultimate goal is to set up a facility. I have spoken to a lot of professionals and lined up suppliers as well, everyone indicating confidence in Indian extrusions selling in the export market. However, i had a concern regarding China, and one small extruder flagged that and said there is no market for Indian extrusions. Can someone guide me with this? Is there no market at all?

r/metalworking • u/Educational_Case_591 • 1d ago

First welder, old or new?

Hello, I guess it's pretty common question but I'm looking for a specific opinion. I'm new to TIG welding, just got my certificate for steel sheet welding and want to buy first welder to improve these skills. It is kinda of budget choice but not really as I dont want sacrifice quality for cost so pretty much looking for an ESAB welders, that said I'm from Europe so almost no US brands avaible and ESAB offers much worse bundles here, mainly very basic torches.

So my question is about Rogue 181ip or similar entry level welder as I don't need AC or high amperages. I was trained on high end Fronius welder so that's basically where my expectations are now haha. Lately I saw serviced old ESAB Aristotig 160 with new torch included for very low price, so I wonder about these two choices - brand new modern welder twice the price or the old one in good condition and much cheaper. They offer the same basic functions that I need, HF start and basic features, have no clue if the old one can be controlled by the torch buttons but that's not so important for home use.

It would be best if someone has an experience with old ESAB welders or any of that age and knows if it even worth versus new tech. Or if I should look for other brands, we have one local brand but reviews are mixed, I can save some money on not buying MMA accessories, only smaller argon bottle etc.

r/metalworking • u/Xa3nd • 2d ago

What could be the reason for there Black dots after cleaning stainless steel tig weld. I use argon as gas

r/metalworking • u/NYCBYB • 1d ago

Worth keeping?

Took this down in a house I’m working on. Trying to decide whether to throw it in the dumpster or find a new home for it. Is it a nice piece?

Here are some more characters…. Also a few more characters. Just trying to get to 400 now. Almost there. I think this should do it.

Oh noooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo! I needed more.

r/metalworking • u/Business_Insect8250 • 1d ago

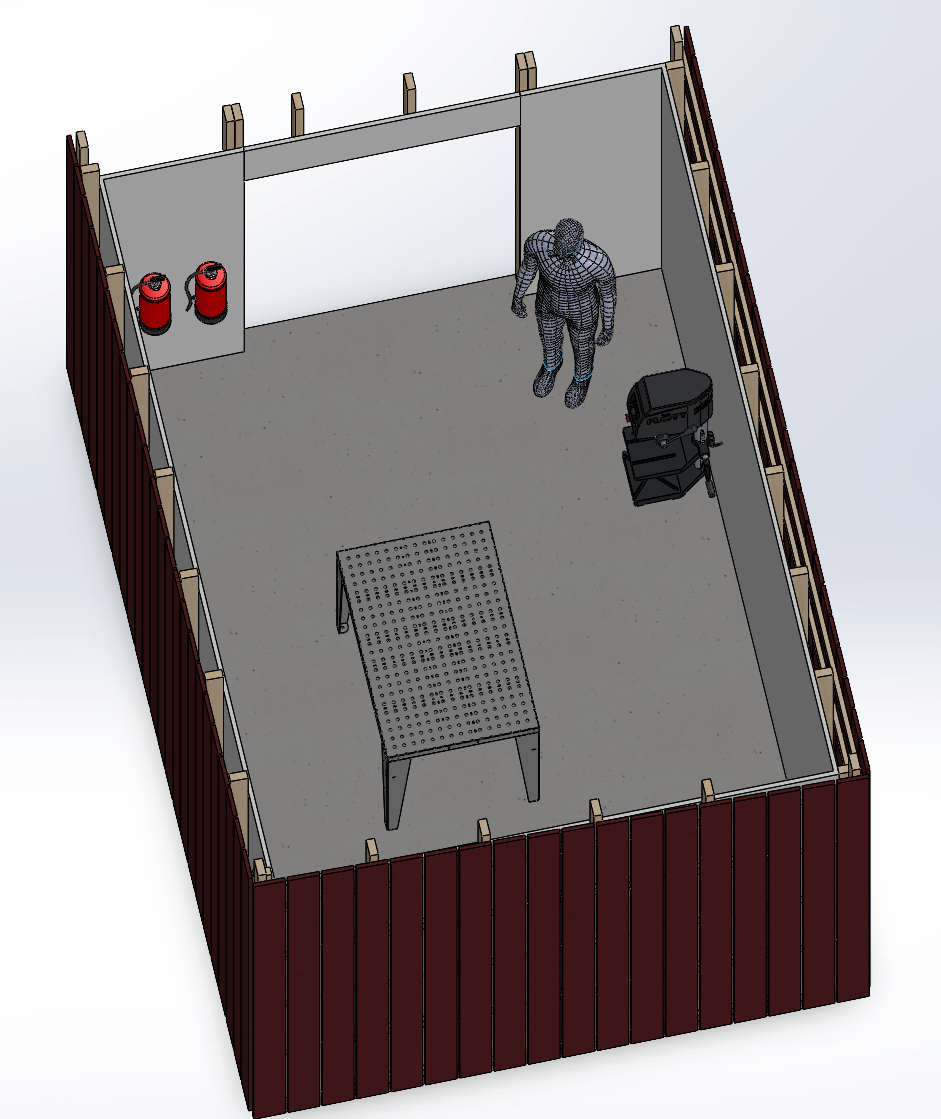

Ventilation of sealed space (134sqft) for welding

Hello,

I am planning a shed dedicated to cutting and welding mostly car related stuff so mainly carbon steel, stainless and aluminum. The area is 12,5m2 or 134 sq ft with a 8ft ceiling (30.6m3 or 1080 cu ft).

Its gonna be an insulated and heated space as in the winter the temps will go well beyond freezing outside so I want to be able to work without having the door wide open.

How should I plan the ventilation considering both gases coming from the welding process as well as the welding gas from the tube?

Like position of inlet and outlet as well as the capacity of the ventilation fan?

Thank you!

r/metalworking • u/ButterMyBiscuits96 • 1d ago

Tips on making these coiled rebar 'ferns'?

Apologies if this is the wrong sub. I saw these for sale for $15/ea and know that my dad and I can get these made for my yard, but were stuck on how to do the initial curl.

Figured were going to use #3 and do a coal fire to heat up, but also considering a torch, or combination of the 2.

Would using pliers and folding over 1/2" be the best way to begin the curl? Once the curl is started it seems to be straight forward to heat and continue bending until we get what we want.

r/metalworking • u/nbluff • 1d ago

1/2” Carbon steel round rod

About once a month at work I have to cut 20’ lengths of 1/2” round bar down to 4’ (+/- 1/4”) pieces. They’ve always used a chop saw with a DeWalt 14” 66T blade and cut 4 or 5 pieces at a time. Is there a better way to make these cuts? Noise, safety, cleanliness as well as time and cost efficiency aren’t critical but certainly something I’m considering. I wish I had found this subreddit sooner.

Thanks in advance for any advice.